Electron beam or laser welding ppt measurement of electron beam polarization at stanford an overview of densification microstructure and mechanical electron beams solved 4 the diagram to right res an old fash.

Electron beam welding ppt.

Electron beam welding process is carried out in vacuum.

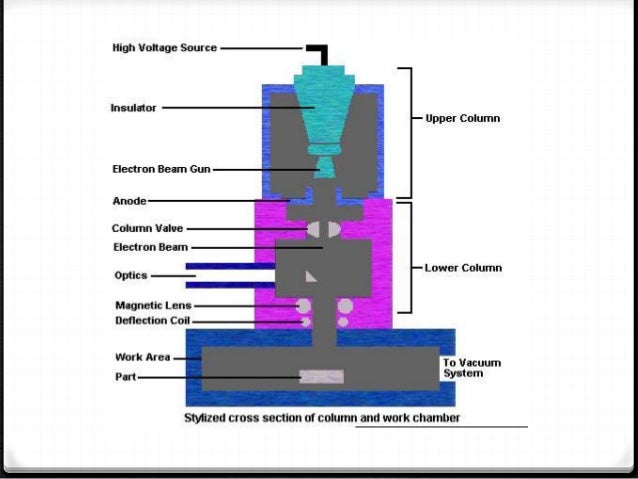

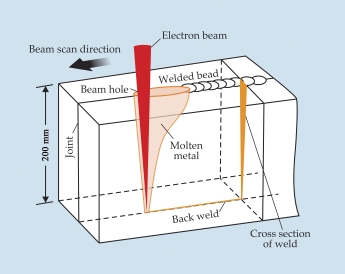

Guided by fig 1 1 electron beam welding the electron beam is produced in a high vacuum environment by an electron gun usually consisting of a tungsten or tantalum cathode a grid or forming electrode and a anode.

The electron beam gun has a tungsten filament which is heated freeing electrons.

A seminar report on beam welding.

The higher the potential difference the higher would be the acceleration of the electrons.

If this technology is downscaled to a micro level i e micro ebw µ ebw it will be able to.

The work piece melt as the kinetic energy of the electrons is transformed into heat upon impact.

A stream of electrons is given off from a tungsten filament heated to about 2200 c.

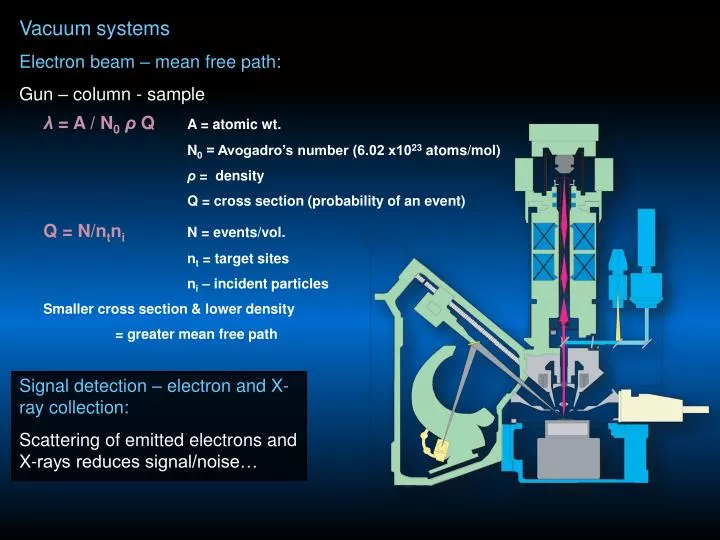

Ebw is often performed under vacuum conditions to prevent dissipation of the electron beam.

In general electron beam welding process is carried out in vacuum.

These electrons are accelerated by applying high potential difference 30 kv to 175 kv between cathode and anode.

In this process electrons are emitted from the heated filament called electrode.

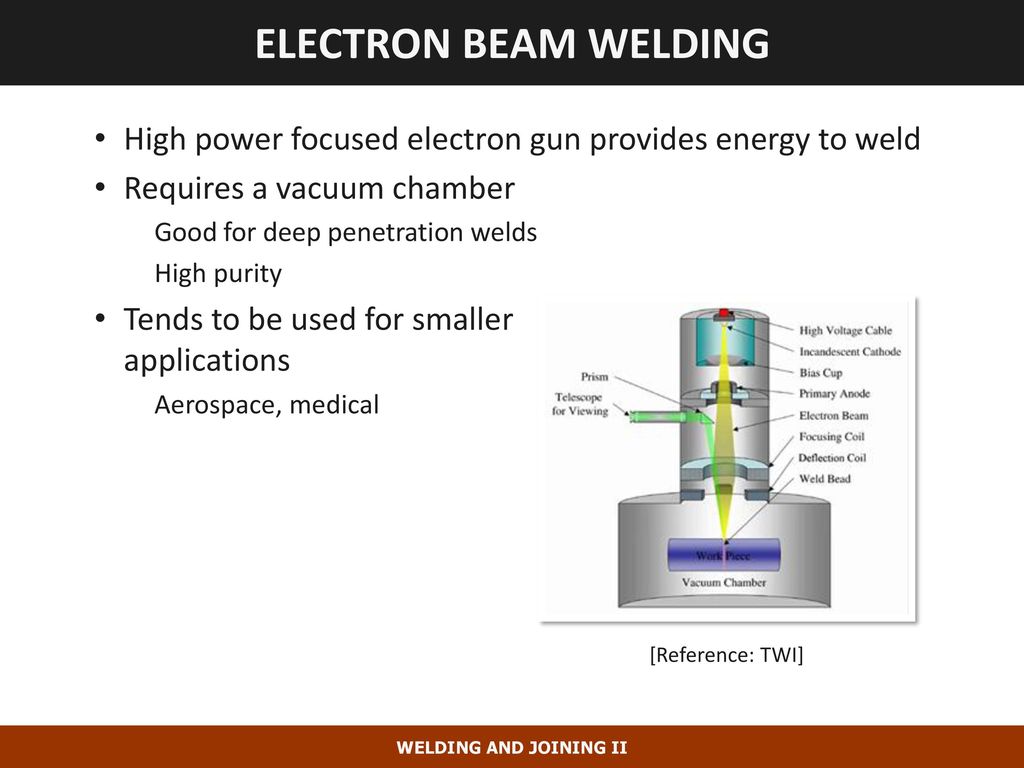

Electron beam welding is a fusion welding process in which a beam of high velocity electrons is applied to two materials to be joined.

The workpieces melt and flow together as the kinetic energy of the electrons is transformed into heat upon impact.

Electron beam welding is a fusion welding process in which a beam of high velocity electrons is applied to the material to be joined.

The electrons are accelerated from the source with high voltage potential between a cathode and anode.

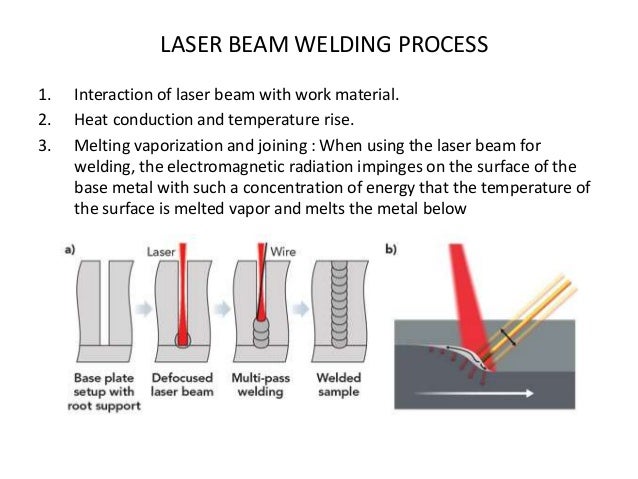

The laser beams have enough energy and when it strikes the metal pieces produce heat that melts the material from the two metal pieces and fills the cavity.

The laser beams are focused to the cavity between the two metal pieces to be joined.

Laser beam welding is a fusion welding process in which two metal pieces are joined together by the use of laser.

Electron beam welding ebw is a well established joining method in the field of manufacturing.

These electrons are accelerated by applying high potential difference 30 kv to 175 kv between cathode and anode.

Download 13 electron beam welding ppt comments.

In this process electrons are emitted from the heated filament called electrode.

The stream of electrons then pass through a hole in the anode.

Share embed 13 electron beam welding ppt please copy and paste this embed script to where you want to embed.